Track tooling costs for each component

This feature allows for careful monitoring of tooling costs for each component, making sure expenses are correctly assigned and enabling better financial management.

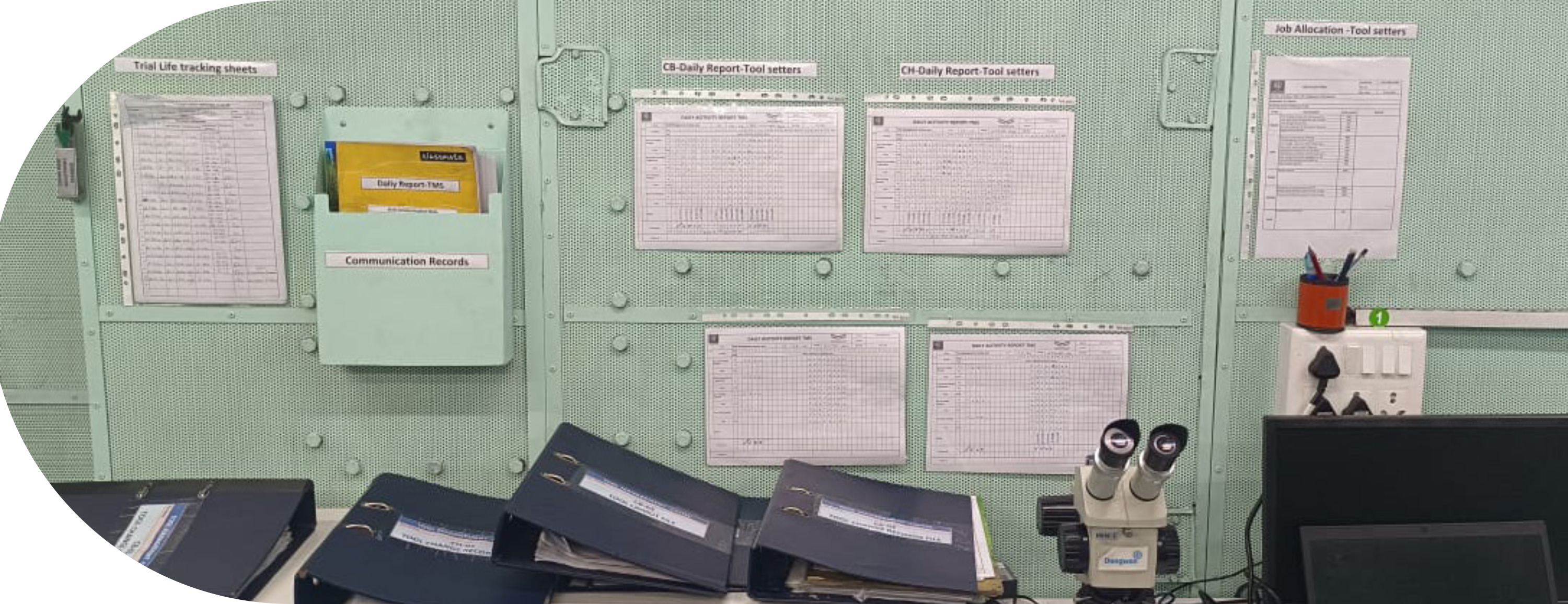

Our tooling cost reporting system is a strong and complete way to track, analyse, and improve tooling expenses and performance across different departments. Here are its main features:

This feature allows for careful monitoring of tooling costs for each component, making sure expenses are correctly assigned and enabling better financial management.

By showing the top 10 tooling costs for each department, managers can focus on the biggest cost areas, ensuring efforts are directed towards reducing the most significant expenses.

This function helps analyze which components have the highest costs per unit, giving insights into where savings can be made, thus lowering overall production costs.

Allows filtering by tool type, department, or time period for targeted insights.

Keeping track of how often tools are changed helps find inefficiencies or maintenance needs, allowing for timely fixes to keep production running smoothly.

By spotting bottlenecks in production, the system recommends tooling upgrades that can make processes smoother and more efficient.

By fixing tooling problems linked to quality, this feature helps reduce defects and production issues, leading to better product quality and less waste.

Regularly checking tool breakage incidents helps find patterns that can be fixed to lower future breakages and costs.

Monitoring and solving unplanned tool changes is key to keeping production running smoothly, as these changes can disrupt workflow and raise costs.

Monitoring vendor visits ensures that suppliers are helping effectively and meeting tooling needs in a timely way.